Boot lab: flex test

Skialper's flex test of ski touring and freeride ski boots

- Author: Martino Colonna

- Photographer: Giovanni Danieli

The range of movement of the cuff is often mentioned, but the most important thing is the force required to move it when walking or skinning.

And what about the flex? The stated numbers provided by brands aren’t standardized. That’s why we took the boots tested, excluding the race and women’s models, to the Sport Technology Lab at the University of Bologna, where we also tested the thermal efficiency of the liners.

Sports equipment is constantly evolving, and to keep up with the pace of innovation, our tests also evolve year on year. That’s why the tests performed on AT boots for the 2023/24 edition of the Buyer’s Guide have been updated and now also include a sustainability analysis of each model. These updates have been made possible by the addition of experts in the field of mechanics, environmental sustainability and AT binding design to the team at the Sport Technology Lab. Compared to previous tests, this time around a different set up was used (including the prosthesis and the binding system) and the recording of data has changed. The latter change aims to simplify the management of the database created for this edition of the Buyer’s Guide.

Flex test: from 1 to 10

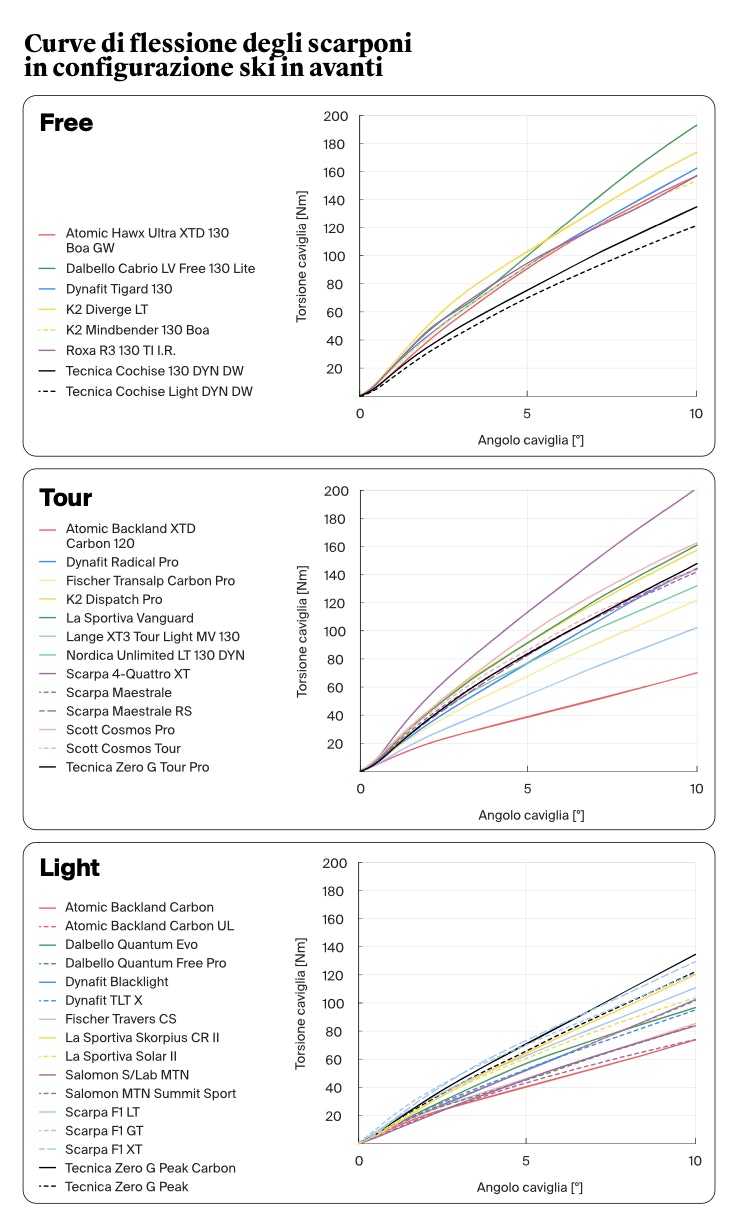

One of the focal points of the tests was, as in previous years, to measure the flex at four different angles (fore, 45°, 90° and aft) to have information on all types of use of the boot in descent.

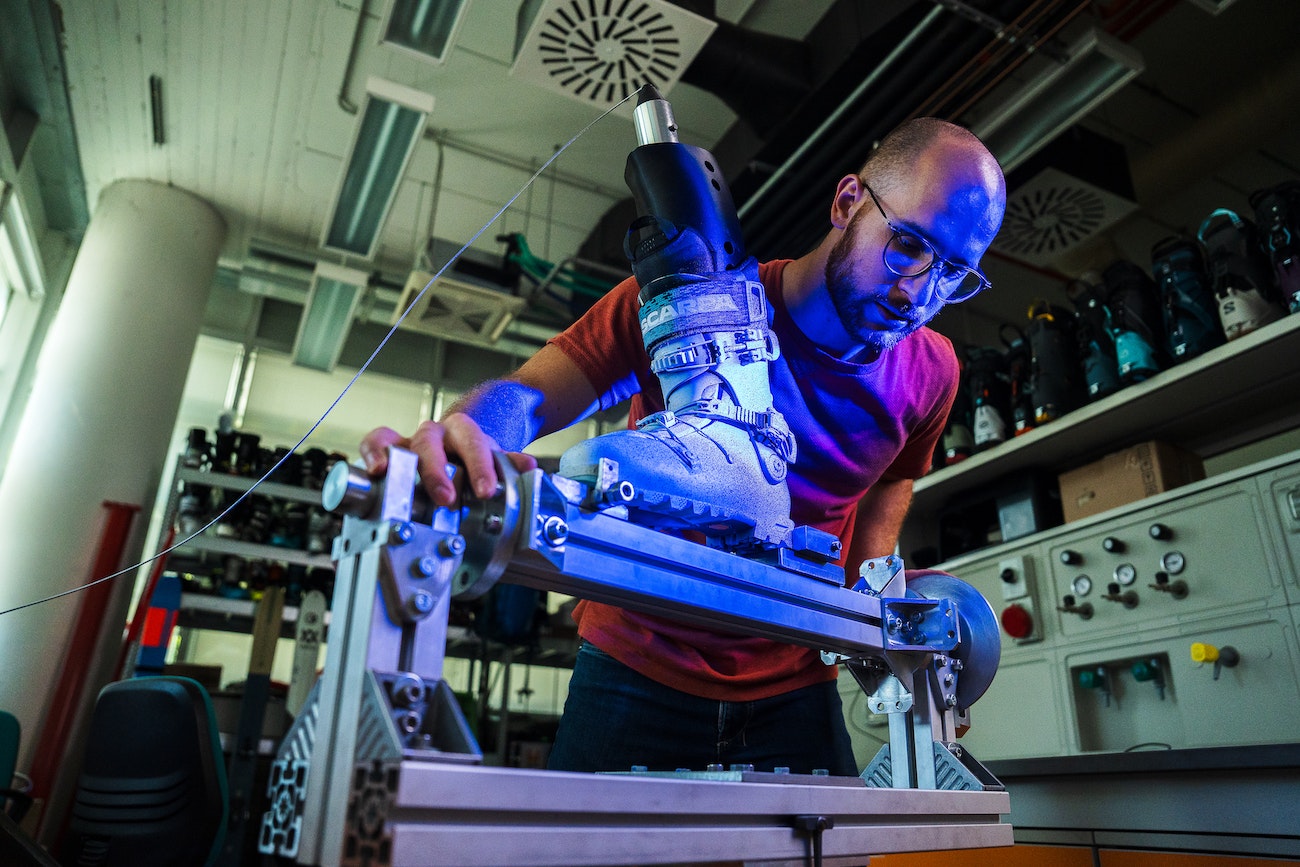

The procedures, the force applied, the tension of the buckle closure and the temperature all remained the same as the previous years. The set up, however, has changed significantly. Firstly, a new 3D-printed prosthetic leg was created using a model from the Z-Anatomy atlas. The anatomical data used were those of a 22-year-old adult male, 172.8 cm (5’8”) tall, weighing 65 kg (143 lbs.). The ankle rotation system was completely changed, using a ball joint to avoid restricting its movement, which could lead to inaccurate results. Mobility was added to the metatarsophalangeal joint in the foot to simulate the way the foot bends when flexing forward. Another important improvement regards the binding system used for the boot.

Whereas beforehand it was firmly locked, this time we used a system that replicated a pin binding connection, in order to obtain more realistic data. Pin bindings provide strong torsional rigidity in the toe of the boot and less in the heel. This effect depends greatly on the angle and position of the force applied. As regards the scale used to present the findings, for each category the data were normalized using a scale of 1 to 10, with 10 being the stiffest at 10° flex in that type of test. This also lets us evaluate the shape of the curve (linear, progressive or regressive, as you can see from the chart).

Walk test: how we did it

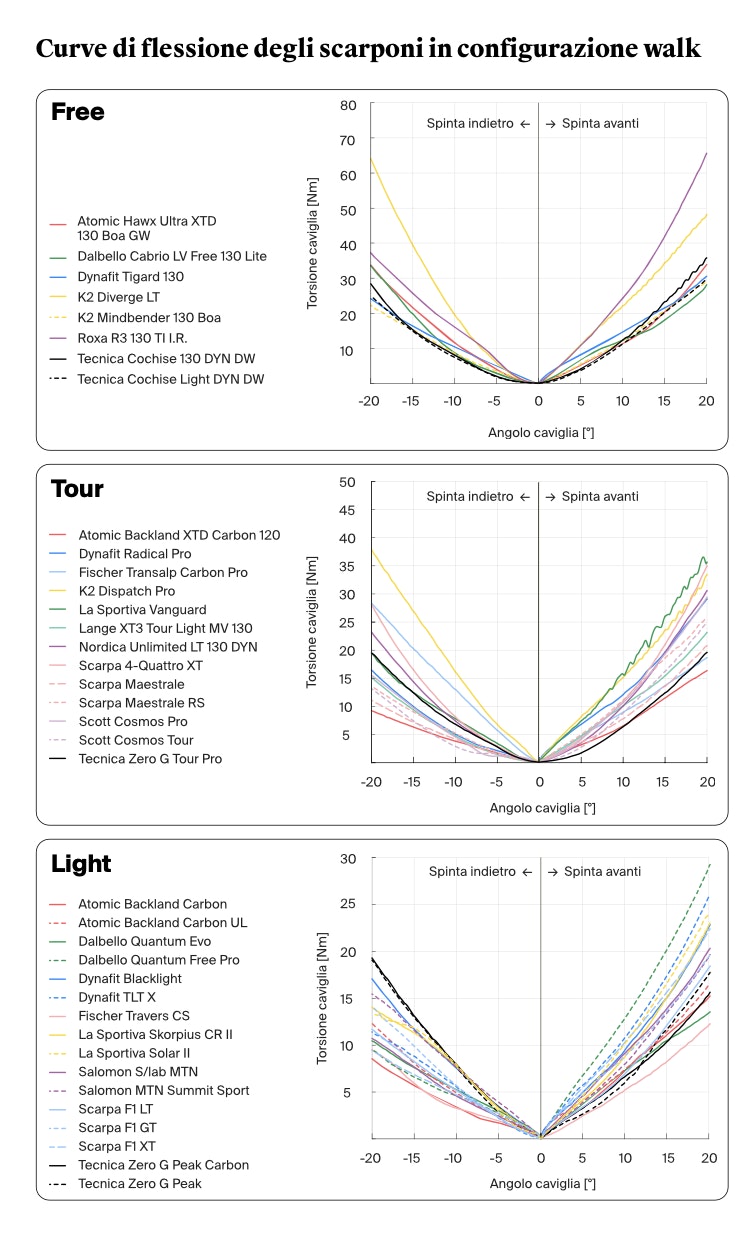

The walk tests were carried out in the same way as previous years, unlocking the ski/walk mechanism and fastening the buckles in the ladder according to manufacturer recommendations. Velcro straps, where present, were left completely open. The boot was attached to the binding in ski mode so we could evaluate the movement between the shell and cuff. The data were recorded as the torque (in Nm) required to reach an angle of 20° to the fore and aft. The full curves are presented here and provide important information on the amount of force necessary to rotate the cuff at different angles, as you don’t always arrive at 20° to the fore or aft when walking.

Tour boots come close to Free boots

The results of the flex tests show that on average the category with the most forward flex is Freeride, with an average of 155 Nm at 10°; followed by Tour, with an average of 140 Nm; then Light, with an average of 100 Nm.

It should, however, be noted that the boot with the stiffest forward flex (with over 200 Nm) is a Tour model (the Scarpa 4-Quattro XT), with the Dalbello Cabrio from the Freeride category showing very similar values. Unlike the Light and Tour boots with both cuff and shell in polyamide, some boots from the Freeride category have parts in polyolefin (like the cuff of the Tecnica Cochise Light DYN GW) or TPU (the shell of the Tecnica Cochise 130). These materials are more temperature sensitive as their stiffness increases as the temperature drops, so it’s conceivable that at 0°C (32°F) they are just as stiff, if not stiffer, than boots made completely from polyamide. The stiffest boot in the Light category is the Tecnica ZeroG Peak Carbon (134 Nm). The flex pattern at 45° and 90° is more consistent as at these angles the binding also undergoes torsion and the results are therefore more level, with decidedly lower values compared to those of the forward flex, with an average of under 100 Nm. Here also there is little difference between the Freeride and Tour categories, demonstrating how many boots in the latter category are now almost as stiff as the former, heavier group. As for the walk tests, you can see how in this case there’s a marked difference between the Light (with an average of 20 Nm to the fore, and 14 Nm to the aft), Tour (26 and 20 Nm), and Freeride (38 and 34) categories. Basically, Tour boots offer better walkability than the Freeride boots despite their similar stiffness on the downhill. The best Freeride boots in terms of walkability are the Tecnica Cochise Light and the Dynafit Tigard, closely followed by the Dalbello Cabrio. In the Tour category, the best was the Atomic Backland XTD, while the best result of the Light boots was the Fischer Travers.

Test protocol

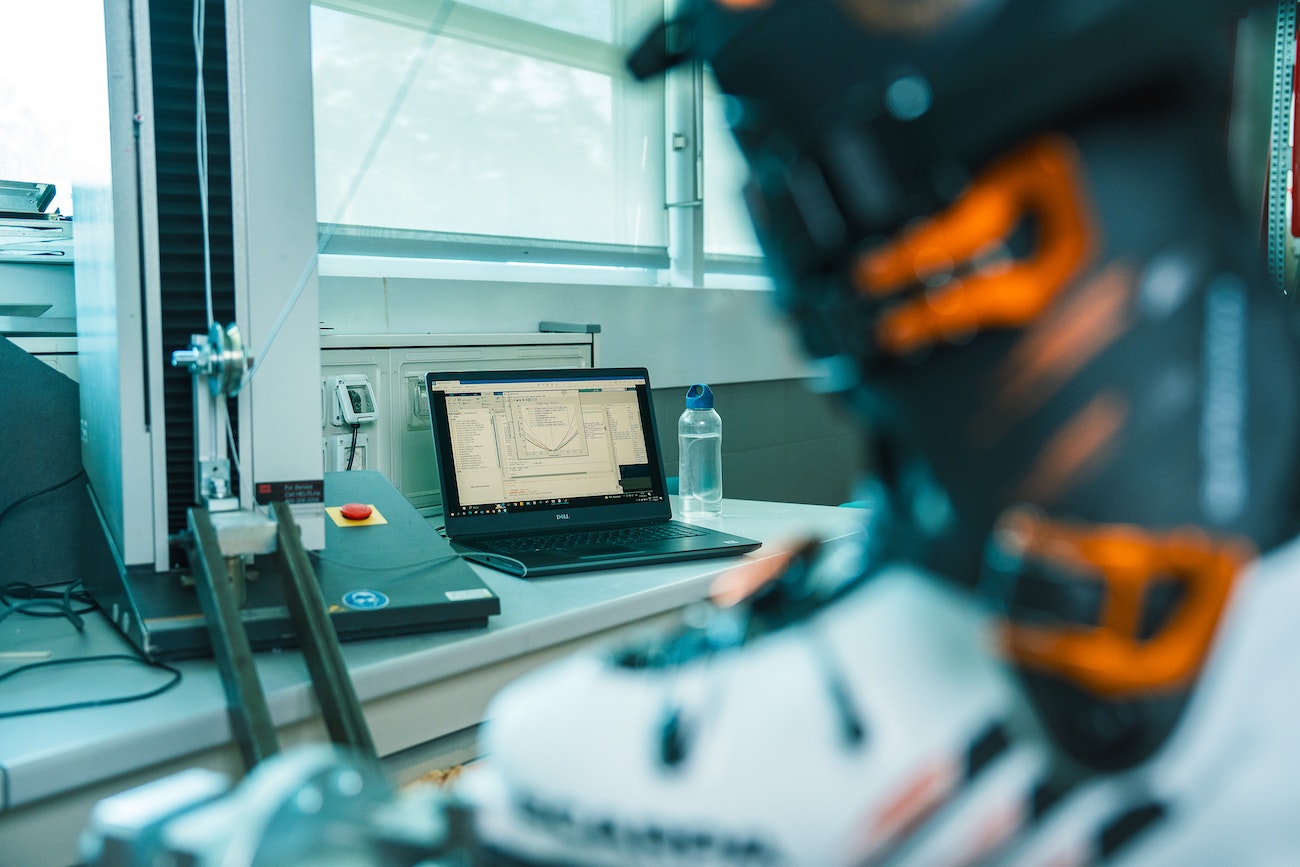

An MTS model Sinergie 200 dynamometer with a speed of 300 mm/min was used for testing the flex. The instrument moves the cable tied to the boot and measures, using a load cell, the force required to pull the cable. The output of the instrument is then a curve that correlates the bending angle (forward and backward) with the torque required to reach that angle. This provides flex curves and not just the force value at a given deflection.

Share this article